mechanical aptitude test gears pulleys pdf

Mechanical aptitude tests assess problem-solving skills in mechanical systems, focusing on gears, pulleys, and their applications. They evaluate understanding of fundamental concepts and practical implementations in real-world scenarios.

What is a Mechanical Aptitude Test?

A mechanical aptitude test is an assessment used to evaluate an individual’s ability to understand and apply mechanical principles. It focuses on problem-solving skills related to gears, pulleys, and other mechanical systems. The test measures a candidate’s knowledge of fundamental concepts, such as gear ratios, pulley functions, and mechanical advantage. It also assesses their ability to interpret diagrams, solve mathematical problems, and think logically about mechanical operations. These tests are commonly used in industries like manufacturing, engineering, and construction to identify candidates with the potential to work effectively with mechanical systems. By analyzing how well someone can apply theoretical knowledge to practical scenarios, employers can gauge their suitability for roles requiring mechanical aptitude.

Importance of Mechanical Aptitude Tests in Hiring

Mechanical aptitude tests play a crucial role in hiring processes for roles requiring technical skills. These assessments help employers identify candidates with strong mechanical reasoning abilities, ensuring they can apply theoretical knowledge to practical scenarios. By evaluating problem-solving skills and understanding of gears, pulleys, and other mechanisms, companies can determine a candidate’s potential to perform effectively in hands-on environments. This reduces the need for extensive training and minimizes workplace errors. Additionally, mechanical aptitude tests ensure workplace safety by confirming that candidates can operate and troubleshoot mechanical systems safely. Overall, these tests are essential for making informed hiring decisions, ensuring candidates align with job requirements, and fostering a competent and efficient team.

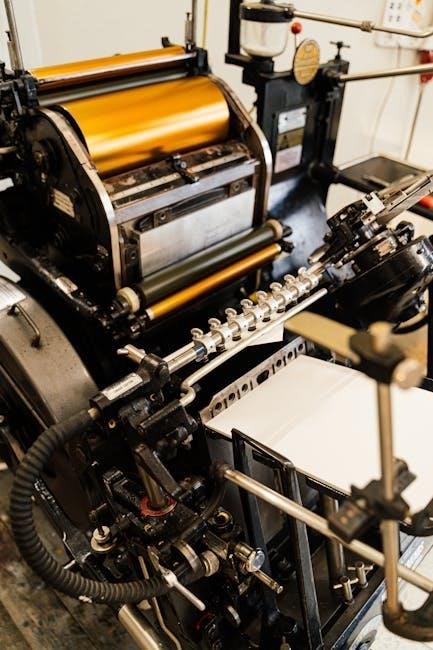

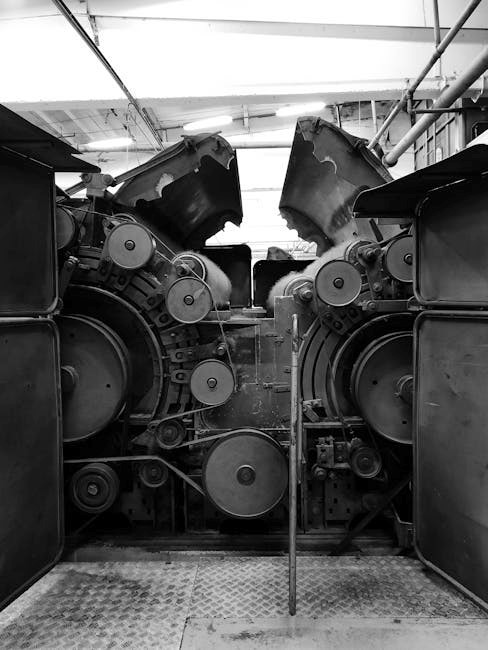

Fundamentals of Gears and Pulleys

Gears and pulleys are essential components in mechanical systems, enabling motion transfer and torque adjustment. Gears mesh to change speed or direction, while pulleys use belts or ropes to alter force direction and mechanical advantage, simplifying operations in machinery.

Basic Concepts of Gears

Gears are fundamental components in mechanical systems, designed to transfer motion and adjust speed or torque between rotating parts. They operate through meshing teeth, which interlock to transmit rotational energy. Gears can be classified into types such as spur, helical, and bevel gears, each serving specific functions. Understanding gear ratios is crucial, as they determine the relationship between input and output speeds. The gear ratio is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driver gear. This concept is essential for solving problems in mechanical aptitude tests, as it directly impacts mechanical advantage and efficiency in various applications, including pulley systems and real-world machinery.

Types of Pulleys and Their Functions

Pulleys are circular wheels mounted on a frame, equipped with grooves to guide ropes, belts, or chains. They are classified into fixed, movable, and compound types. Fixed pulleys change the direction of force application but do not alter the magnitude, while movable pulleys change both direction and force, providing mechanical advantage. Compound pulleys combine fixed and movable pulleys to increase mechanical advantage further. Additionally, pulleys can be categorized by their use, such as step pulleys for adjusting speed and timing pulleys for precise synchronization. Understanding these types and their functions is vital for solving problems in mechanical aptitude tests, as pulleys are integral to various mechanical systems and their applications in real-world scenarios.

Understanding Mechanical Aptitude Test Format

Mechanical aptitude tests are multiple-choice, often including diagrams and time limits, assessing problem-solving skills related to gears, pulleys, and mechanical systems.

Common Question Types in Mechanical Aptitude Tests

Mechanical aptitude tests feature multiple-choice questions, often with diagrams, requiring problem-solving skills. Common question types include gear ratio calculations, pulley system problems, and mechanical advantage questions. They also assess understanding of torque, friction, and basic physics principles. Many questions involve numerical reasoning, where candidates must interpret data and apply mathematical operations to find solutions. Practical scenarios, such as troubleshooting gear mechanisms or determining the correct pulley configuration, are frequently included. Time constraints and the need to visualize mechanical systems add to the challenge. These questions evaluate both theoretical knowledge and the ability to apply it in real-world situations, ensuring candidates possess the necessary skills for technical roles.

Time Management Strategies for Test-Takers

Effective time management is crucial for success in mechanical aptitude tests. Candidates should allocate specific time to each question, avoiding spending too long on complex problems. Skimming through the test initially to identify easier questions can help build confidence and save time for challenging sections. Prioritizing questions that play to your strengths ensures maximum scoring potential. Practicing under timed conditions during preparation helps improve speed and accuracy. Additionally, eliminating obviously incorrect answers before selecting the best option reduces errors. Staying calm and focused throughout the test is essential to maintain clarity of thought. By balancing speed and precision, test-takers can efficiently complete the test within the allotted time.

Key Topics Covered in Mechanical Aptitude Tests

Mechanical aptitude tests cover essential topics like gear ratios, pulley systems, torque, and mechanical advantage, ensuring a solid understanding of fundamental mechanical principles and their practical applications.

Gear Ratios and Their Calculations

Gear ratios are a critical component of mechanical aptitude tests, representing the relationship between the number of teeth on two meshing gears. The gear ratio is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driving gear; This ratio determines the torque and speed relationship between the gears, with higher ratios indicating greater torque but lower speed. Understanding gear ratios is essential for analyzing mechanical systems, as they directly impact the performance and efficiency of machinery. Test questions often require candidates to apply formulas, such as Gear Ratio (GR) = Number of Driven Teeth / Number of Driving Teeth, to solve problems involving torque, rotational speed, and mechanical advantage. Mastery of these calculations is vital for success in mechanical aptitude assessments.

Pulley Systems and Mechanical Advantage

Pulley systems are integral to mechanical aptitude tests, as they demonstrate how mechanical advantage is achieved through the use of wheels and ropes. A pulley system’s mechanical advantage is calculated by dividing the load by the effort applied, often enhanced by adding more ropes or using movable pulleys. Fixed pulleys change the direction of force but do not reduce effort, while movable pulleys reduce effort at the cost of increasing the distance over which force is applied. Compound systems, combining multiple pulleys, maximize mechanical advantage further. Understanding these principles is crucial for solving test questions involving pulley configurations, force calculations, and efficiency. Mastery of pulley mechanics is essential for assessing how systems amplify force in real-world applications, making it a cornerstone of mechanical aptitude assessments.

Practical Applications of Gears and Pulleys

Gears and pulleys are essential in mechanical systems, enabling efficient power transmission. They are widely used in industries for lifting, speed reduction, and torque multiplication, enhancing operational efficiency.

Real-World Examples of Gear and Pulley Systems

Gears and pulleys are integral to everyday machinery. In bicycles, gears enable speed adjustment, while pulleys in elevators facilitate smooth vertical movement. Industrial machinery relies on gear systems for torque and speed modification, and pulleys are used in conveyor belts for material transport. Additionally, wind turbines and automotive transmissions utilize gears for efficiency, and pulleys are essential in cranes for lifting heavy loads. These systems demonstrate how gears and pulleys work together to enhance mechanical operations across various industries.

Troubleshooting Common Issues in Gear and Pulley Mechanisms

Troubleshooting gear and pulley systems involves identifying and resolving issues like misalignment, excessive wear, or improper lubrication. Misalignment can cause vibrations and premature wear, requiring adjustment of gear or pulley positions. Excessive wear often results from inadequate lubrication or overload, necessitating replacement of worn components. Belt slippage in pulley systems can be addressed by tightening the belt or adjusting tension. Noise or overheating may indicate faulty bearings or improper gear ratios, requiring inspection and recalibration. Regular maintenance, such as lubrication checks and alignment verification, helps prevent these issues. Understanding these common problems and their solutions is critical for ensuring the efficiency and longevity of mechanical systems.

Preparing for the Mechanical Aptitude Test

Preparing for the test involves utilizing study guides, practicing with sample questions, and understanding fundamental mechanical principles to enhance problem-solving skills and time management.

Study Materials and Resources for Practice

Effective preparation for mechanical aptitude tests requires access to quality study materials. Online platforms like JobTestPrep offer practice tests and detailed explanations to familiarize candidates with test formats. Textbooks on mechanical reasoning provide in-depth knowledge of gears, pulleys, and other mechanical systems. Additionally, YouTube tutorials and online forums offer visual explanations and interactive exercises. Practice PDFs and downloadable guides from websites such as Mechanical Aptitude Test Guide are valuable resources. These materials help candidates understand fundamental concepts, practice problem-solving, and improve time management skills. Utilizing a combination of theoretical study and practical exercises ensures comprehensive preparation for the test.

Strategies to Improve Problem-Solving Skills

Improving problem-solving skills for mechanical aptitude tests requires a strategic approach. Start by understanding the fundamental principles of gears, pulleys, and mechanical systems. Practice breaking down problems into smaller, manageable parts, focusing on identifying key components and relationships. Visualize mechanical systems to better comprehend how they operate. Regularly solve practice questions and review explanations to refine your understanding. Time yourself to enhance speed and accuracy. Additionally, study real-world applications to contextualize your learning. Reviewing mistakes and learning from them is crucial for long-term improvement. Consistent practice and a systematic approach will help build confidence and proficiency in tackling complex mechanical problems effectively.

Mastery of gears and pulleys is essential for excelling in mechanical aptitude tests. Regular practice and a deep understanding of principles ensure success in these assessments.

Final Tips for Success in Mechanical Aptitude Tests

Success in mechanical aptitude tests requires a combination of knowledge and strategic preparation. Start by thoroughly understanding the fundamentals of gears, pulleys, and their applications. Practice numerical reasoning and problem-solving skills to improve speed and accuracy. Utilize online resources and practice tests to familiarize yourself with the test format. Review gear ratios, mechanical advantage, and common pulley systems to build confidence. Time management is crucial, so allocate your time wisely during the test. Stay calm and methodical, ensuring you understand each question before answering. Lastly, learn from your mistakes by reviewing incorrect answers post-test. Continuous practice and a deep understanding of mechanical principles will significantly enhance your performance.