burning test of fibres pdf

The burning test is a simple method to identify fibre types by observing burning behavior, odour, and residue, crucial for textile quality control and safety standards.

1.1 Importance of Fibre Identification in Textiles

Fibre identification is crucial for predicting textile behavior in various environments and planning appropriate treatments. Knowing the fibre type helps determine care instructions, ensuring safety and durability. Accurate identification is essential for quality control, labeling, and meeting consumer expectations. It also aids in detecting synthetic blends in natural fabrics, ensuring compliance with safety standards. Fibre identification is a fundamental step in textile science, influencing both practical applications and consumer trust in fabric quality and performance.

1.2 Overview of the Burning Test Method

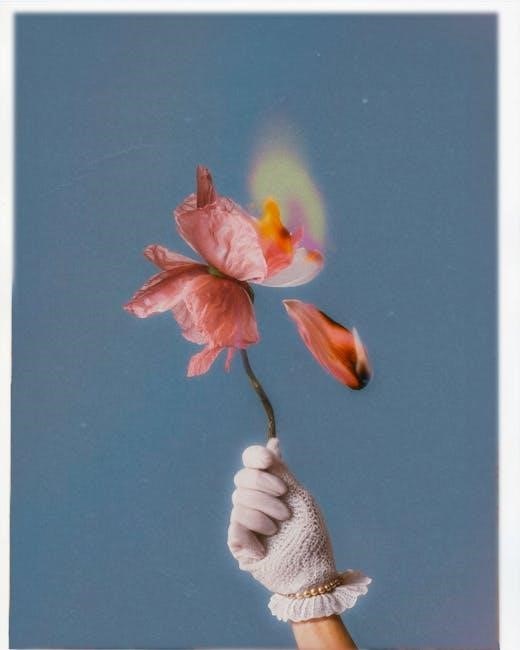

The burning test involves igniting a fabric sample to observe its burning behavior, odour, and residue. Key observations include whether fibres burn quickly, melt, or shrink from the flame. Natural fibres like cotton and wool burn completely, leaving a powdery ash, while synthetics like polyester melt, producing a hard bead. The test is non-technical, requiring minimal equipment, making it accessible for fabric identification. It helps distinguish natural from synthetic fibres and detects blends, ensuring accurate fibre content determination essential for textile quality control and safe consumer use.

Key Observations in the Burning Test

The burning test reveals fibre characteristics like burning speed, odour, and residue type, aiding in accurate fibre identification and distinguishing natural from synthetic fibres effectively.

2.1 Burning Speed and Melting Point

Burning speed and melting point are critical indicators in fibre identification. Natural fibres like cotton burn quickly with a yellow flame, while synthetic fibres such as polyester and nylon melt and burn slower, often with a distinct curling or shrinking effect. The melting point varies significantly, with synthetics typically melting at higher temperatures compared to natural fibres. Observing these characteristics helps differentiate fibre types, providing valuable insights into their composition and origin.

2.2 Odor Produced During Burning

The odor produced during the burning test is a crucial indicator in fibre identification. Natural fibres like cotton and linen emit a smell similar to burning paper, while wool produces a distinct odour reminiscent of burning hair. Synthetic fibres, such as polyester and nylon, generate strong chemical or plastic-like smells. These differences in odour help differentiate fibre types. For instance, acrylic fibres may produce a sweetish or acrid smell. Considering

2.3 Type of Ash Residue

The type of ash residue is a critical factor in fibre identification. Natural fibres like cotton leave a light, feathery ash, while wool produces a dark, brittle residue. Silk fibres result in a similar ash to wool but with a more fragile texture. Synthetic fibres, such as polyester and nylon, often leave behind hard, shiny beads. Acrylic fibres, however, produce a soft, fuzzy residue. These distinct ash characteristics help distinguish between fibre types, making the burning test a reliable method for fibre identification in textiles. The residue’s appearance and texture provide clear indicators of the fibre’s origin and composition.

Burning Characteristics of Natural Fibres

Natural fibres like cotton, wool, and silk exhibit distinct burning behaviors. Cotton burns quickly with a paper-like smell, while wool and silk shrink and emit a burnt hair odor.

3.1 Cotton Fibres

Cotton fibres burn rapidly, producing a bright yellow flame and a light, paper-like ash. When ignited, they emit a smell similar to burning paper, leaving a feathery residue. This characteristic behavior helps distinguish cotton from other natural and synthetic fibres, making the burning test a reliable method for identification. The fibre’s cellulosic nature contributes to its quick combustion and distinctive odour, which are key indicators in fibre analysis.

3.2 Wool Fibres

Wool fibres burn with a smouldering flame, producing a strong, unpleasant odour reminiscent of burning hair. When ignited, wool shrinks from the flame and forms a brittle, black, crumbly residue. The burning process is relatively slow compared to cotton, and the fibre often curls away from the heat source. This unique combination of characteristics makes wool easily identifiable through the burning test, distinguishing it from both natural and synthetic fibres. The distinct odour and residue patterns are key indicators for recognizing wool in fibre blends or mixed fabrics.

3.3 Silk Fibres

Silk fibres burn slowly, producing a sizzling sound and a faint, smoky odour similar to burning hair. When ignited, silk curls away from the flame, forming a dark, brittle residue that is easily crumbled. The fibre melts slightly before burning completely, leaving behind a hard, black ash. This distinctive behaviour helps identify silk, as it burns more slowly than cotton but faster than wool. The combination of its burning pattern, odour, and residue makes silk easily distinguishable from other natural and synthetic fibres in the burning test.

Burning Characteristics of Synthetic Fibres

Synthetic fibres like polyester, nylon, and acrylic melt and burn with a chemical odour, producing hard, plastic-like residues that often shrink or drip away from the flame.

4.1 Polyester Fibres

Polyester fibres burn with a strong chemical odour and melt, forming hard, bubbly beads. They do not produce a soft ash like natural fibres. When ignited, polyester shrinks away from the flame and often drips, creating a plastic-like residue. This behaviour helps distinguish polyester from natural fibres in textile identification. The burning test is essential for quality control and fabric labeling, ensuring accurate fibre content disclosure. Synthetic fibres like polyester have distinct burning characteristics, making the burn test a reliable method for fibre identification in the textile industry.

4.2 Nylon Fibres

Nylon fibres burn with a distinctive celery-like odour and melt, forming hard, shiny beads. They tend to curl and shrink away from the flame. Nylon does not produce a soft ash residue, unlike natural fibres. When exposed to heat, nylon melts and drips, creating a plastic-like texture. This behaviour is characteristic of synthetic fibres and aids in distinguishing nylon from natural or blended fabrics. The burning test effectively identifies nylon’s unique properties, making it a valuable method for fibre analysis in textile production and quality assurance processes.

4.3 Acrylic Fibres

Acrylic fibres burn with a chemical-like odour and tend to shrink away from the flame. They melt and form hard, plastic-like beads that are brittle to the touch. Unlike natural fibres, acrylic does not produce a soft, fluffy ash residue. Instead, it leaves a hard, shiny bead. This behaviour is typical of synthetic fibres and helps differentiate acrylic from natural or blended fabrics. The burning test is an effective way to identify acrylic fibres, as their unique properties, such as melting and hardening, are distinct and easily observable during the process.

Comparison of Natural and Synthetic Fibres

Natural fibres burn with a paper-like smell and leave soft ash, while synthetics emit chemical odours, melt, and form hard residues, aiding clear differentiation.

5.1 Differences in Burning Behavior

Natural fibres like cotton and wool ignite easily, burn quickly, and leave behind soft ash. Synthetic fibres such as polyester and nylon melt, shrink from flames, and emit chemical odours, producing hard, shiny residues. These distinct behaviors help differentiate between fibre types, with natural fibres typically burning completely and synthetics often self-extinguishing or forming beads. The variations in burning characteristics are crucial for accurate fibre identification in both industrial and domestic settings, ensuring proper material classification and safety standards are maintained; This method is widely trusted for its simplicity and effectiveness.

5.2 Identifying Blends Through Ash Residue

The ash residue from burning fabrics can reveal fibre blends, as natural and synthetic fibres produce distinct residues. Natural fibres leave soft, fluffy ash, while synthetics form hard, shiny beads. Blends often show a mix of both, indicating combined fibre types; This method is valuable for quality control and fabric labeling, helping to verify material composition. By analyzing the residue’s texture and appearance, one can identify if a fabric is pure or blended, ensuring accurate fibre identification and compliance with textile standards. This simple yet effective technique aids in maintaining product integrity and consumer trust.

Practical Applications of the Burning Test

The burning test is widely used in quality control and fabric labeling to ensure accurate fibre identification and consumer safety.

It helps maintain textile industry standards and verify material composition for reliable product information.

6.1 Quality Control in the Textile Industry

The burning test is a vital tool in ensuring textile quality control, helping to verify fibre composition and meet industry standards. By analyzing how fabrics burn, textile manufacturers can detect synthetic blends in supposedly natural fibres, ensuring product authenticity. This method also aids in maintaining consistent fabric performance and safety. Regular use of the burning test ensures compliance with safety regulations and customer expectations, making it an essential practice in the textile production process.

6.2 Fabric Labeling and Consumer Safety

Accurate fabric labeling ensures consumers know the fibre content, crucial for care and safety. The burning test helps verify fibre identity, ensuring truthful labeling. Detecting synthetic blends in natural fabrics prevents potential fire hazards. This method protects consumers by confirming fabrics meet safety standards, especially for garments. Correct labeling also guides proper fabric use, avoiding damage or risk. Thus, the burning test is vital for safeguarding consumers and maintaining trust in textile products.

The burning test effectively identifies fibre types, ensuring accurate textile classification and safety standards, making it a crucial tool in the textile industry for quality assurance.

7.1 Summary of the Burning Test Method

The burning test method involves observing fibre behavior when exposed to flame, noting characteristics like burning speed, odour, and residue type. This technique helps determine fibre composition and distinguish between natural and synthetic materials. By analyzing these properties, one can accurately identify the fibre type, crucial for textile quality control, fabric labeling, and ensuring consumer safety. The method is straightforward and cost-effective, making it a valuable tool in the textile industry for fibre identification and classification purposes.

7.2 Importance of Accurate Fibre Identification

Accurate fibre identification is crucial for ensuring consumer safety, meeting regulatory standards, and maintaining textile quality. Identifying fibres correctly ensures proper care and durability of fabrics, preventing damage from inappropriate treatments. Misidentification can lead to safety hazards, such as using flammable materials in inappropriate contexts. Accurate fibre identification also supports sustainability by enabling the use of materials with minimal environmental impact. This process is essential for textile manufacturers, consumers, and regulators to make informed decisions and uphold quality and safety standards in fabric production and use.